- Lead Connectors & Cable Assemblies Manufacturer Since 2001

- +86-769-82851583

- +86-133-16884280

- [email protected]

Top 5 Advantages of Custom Cable Assemblies

Wire to wire connectors Scondar manufacturer

January 10, 2017Is a generic cable setup not meeting your specifications and needs? Perhaps you need to step up your game. When it comes to dealing with complicated cable application and the old-school way doesn’t seem to work anymore, custom cable assembly should be your first choice.

It is important to purchase the correct cables for a specific application. You need to bear in mind that poorly done wiring or perhaps utilization of substandard cables can create technical connector issues. This will further lead to a temporary system shutdown which causes disasters.

It is true that standard cables’ performance is pretty decent, however custom cable assemblies has its own benefits; far more than what standard cables can offer. Let’s get to know the different advantages of custom cable assemblies below.

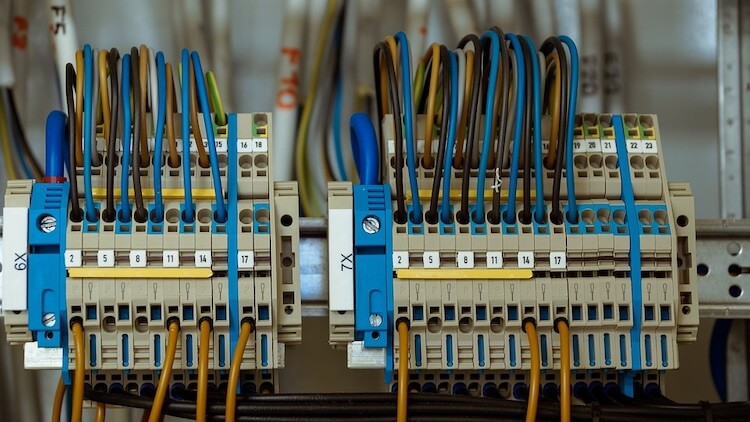

Adaptability and Accuracy

Custom cables are indeed very flexible in a way that each cable length can be made as per the project specifications. The specific number of cables can be bought depending on the required specifications of your application. After the assembly is completely done, there should be zero extra cables left.

This will make the installation tidy and clean without the need to put away extra wires and cables that will surely add up some space. Custom cables are also created as per client’s design specification, hence every detail should be accurate to fit into the level of tolerance for custom cable assembly.

Here are some industries where custom cable assemblies can be used:

- Enhancement of Electronics —— custom cables provide greater help to the world of telecommunications. To be more specific, the utilization of laptop, smartphone, computer, or any device that needs a network cable helps in transferring data faster. Custom cables for fiber optics are great for vital network performances, especially when standard cable patches fail.

- Great for Military Needs —— from securing confidential data to powering military bases overseas, and field unit communication, custom cables are a huge help to the military. Not only that, these cables are able to withstand during harsh weather conditions and intense environmental exposure, most especially during missions.

- Medical Field —— the medical industry is one of the industries that has a meticulous wiring and cable assembly specifications. High temperatures and huge moisture for medical instrument sterilization, make custom cables degenerate faster. Because of these aspects, the medical industry definitely needs a cable system that can hold out these repetitive all day same exposure. Hence, custom cables are the best option to sustain all these.

Required Materials

All necessary materials required for cable construction, such as jacketing materials, insulation, and cable protection can all be itemized to suit the system application requirement. As for the manufacturing process and materials sources control, they can also be catered in the event of crucial applications depending on the line of industry.

Responsibility and Quality

The person in charge to handle your custom cable assembly is someone who has a close contact with the cable/connector manufacturer. Hence, the manufacturer is responsible for the standard and quality of the custom cables bought. He/She guarantees that after the installation the custom cable assemblies should be fully functional.

Being said that, manufacturers must run a few tests to ensure that the cable system us tested for different elements before the assembly phase. Cables should be tested for — heat tolerance, chemical exposure resistance, temperature, and electrical parameters.

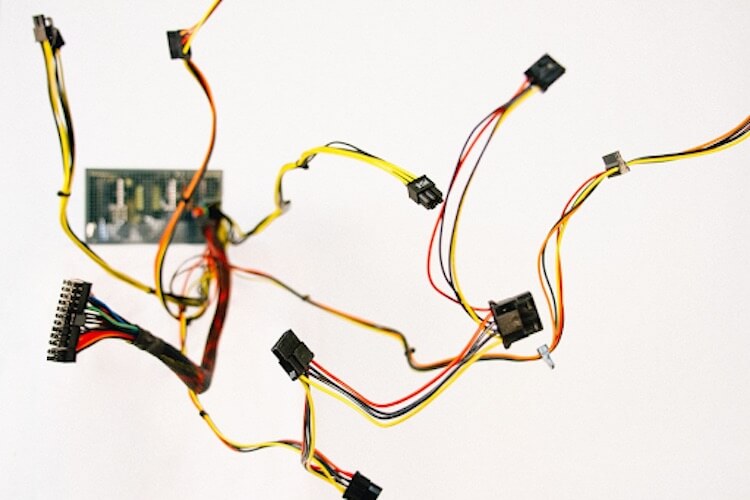

Various Functionality

Custom cables can be manufactured to manage different functionalities under a single cable, such as coax, cable shielding, optical fibre, signal power, and a lot more. This process is for specialized applications like security, network system, etc..

Cost Friendly

Most cable manufacturers provide extra services like design assistance for selecting the most ideal custom cable assembly for a certain application. These services will greatly benefit you in terms of cost saving since other manufacturers require additional fees when you ask for extra help.

Conclusion

Custom cable assemblies are far more beneficial compared to its standard and bulk cable counterparts. Because of the evolving technology that require sophisticated specifications, custom cables are believed to do justice to every requirement needed. More and more cable manufacturers are stepping up their game in manufacturing various cables and wiring systems that cater different industry applications.

What’s more, with custom cable assemblies, perhaps we need to think about how to give them a shell that will extend their life. The shell, such as LED strip aluminum profile, can greatly reduce the wear of custom cable assemblies, which can surely improve the benefits.

References:

https://www.travelers.com/resources/home/smart-home/5-smart-home-automation-safety-tips